Value Engineering Services

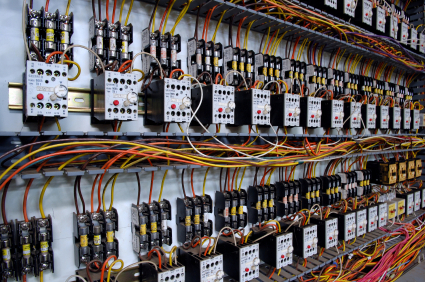

Control Panel Design

Design and assembly cannot be isolated. A design engineer must understand how his designs are manufactured on the floor, and assembly staff can do a better job when they understand why a particular specification is critical to the outcome of the project. That’s why we take an integrated “design to production” approach to your custom control panels. Our engineers are experts in Design for Manufacturability (DFM) and Value Engineering of products.

We’ll review every aspect of the design before manufacture begins. We identify any potential problems and locate areas where a small change can significantly decrease costs or improve the quality of the final product. We’ll help select the right materials, find ways to make control panels more durable, develop solutions for demanding environments, and create manufacturing systems that ensure high levels of repeatability and quality control.

We bring decades of experience in multiple fabrication techniques - injection molding, casting, extrusions, stamping, die cutting and CNC machining - to bear on each project, evaluating the right way to manufacture each component. We also understand the opportunities and limitations of each type of material, from plastics to metal to fiber optic glass, and all of the connectors your harness requires.

Our designers can assist you in any part of the project, reviewing current designs or helping you design control panels from scratch. Using AutoCad (ACAD) or Solidworks, our team can develop or support your control panel design efforts to make sure that your project successfully makes its way from the drawing board to your operation.