Value Engineering Services

Truck & Trailer Wire Harnesses

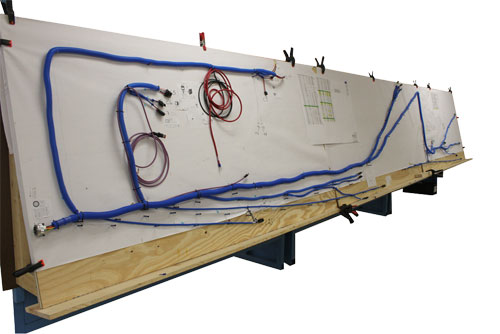

Trucks may drive from muddy slush or icy cold to searing, dusty heat on the same run. So every part of the trailer, including the electrical system, must be able to withstand the broadest range of operational conditions. At Cypress Industries, we build custom wiring harnesses for rigs of all types, from the lift trucks that load and unload ships to the semi-trailers that haul goods from one shore to the other. We’ll evaluate the full range of environmental stresses your trucks endure, and build dependable truck wiring harnesses that keep your equipment running, no matter where they need to go.

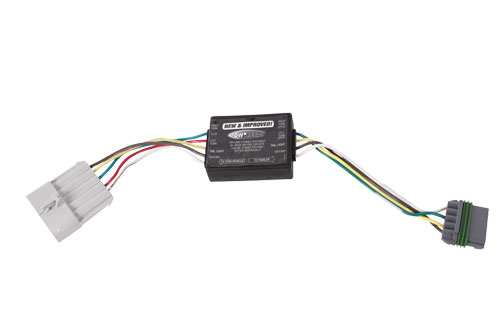

Our custom braiding equipment allows us to craft the most rugged trailer wire harnesses available, keeping the cab in control of every part of the electrical system, from lights to braking. We also develop custom potting for your harnesses or connectors to improve durability and minimize replacement costs, fabricating just the right materials for each application. We’ll work from your drawings or work with you to develop manufacturing processes for trailer hitch wiring harnesses that can withstand abrasion, water, shock, vibration, corrosion and temperature extremes.

And once you’ve built a harness with Cypress, you’ll get the same level of quality in every production run. Our high-end ERP systems include extensive documentation covering all aspects of design, materials and production so we can build new trailer wiring harnesses as needed with exceptional repeatability. We’ll also manufacture and warehouse large or small volumes of individual components or complete truck wiring harnesses to provide you with the smallest possible turn times and the largest return on your investment.

![]() As freight and logistics become such an important part in the supply chain, many companies throughout the USA and internationally are developing new and improved technologies to advance solutions. These include several different trucking capabilities as well as trailers, both standard and refrigerated (reefers), and international container travel. We provide solutions in all of these areas by working closely with the Engineering Departments of our customers, we are capable of producing a final product that meets or exceeds their requests and demands.

As freight and logistics become such an important part in the supply chain, many companies throughout the USA and internationally are developing new and improved technologies to advance solutions. These include several different trucking capabilities as well as trailers, both standard and refrigerated (reefers), and international container travel. We provide solutions in all of these areas by working closely with the Engineering Departments of our customers, we are capable of producing a final product that meets or exceeds their requests and demands.

We have the capabilities of changing, revising, updating, and/or implementing new solutions into any cable assembly we build. With an extensive amount of stock of Deutsch, Waypack, Delphi and all standard connecters utilized in the industrial transportation industry, Cypress can quickly turn any product and deliver to their customers for test or deployment into the field.

Matt,

President