Value Engineering Services

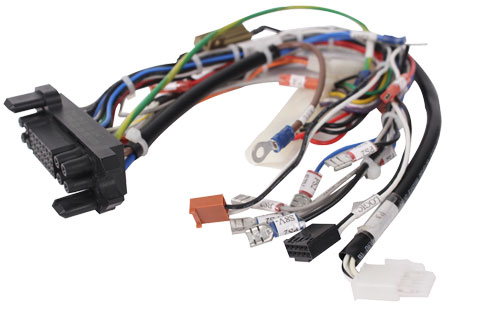

Industrial Cable Assemblies

Industrial cable assemblies must be as dependable as every part of the equipment they control. To minimize downtime, maximize ROI and manage your operations, you need a cabling system that provides complete control and provides the right data at the right time.

Cypress Industries works with companies in a wide range of fields to build rugged cable assemblies that maintain their integrity in every sort of environment. We meet the demands posed by mining, underwater drilling and road construction by examining the atmospheric stresses that equipment endures and designing rugged cable assemblies that keep operators in control. The extraordinary tensile strength and durability requirements of a wide range of equipment, including tools used in agriculture, baggage handling, wind power, solar power, and HVAC applications, demands industrial cable assemblies that withstand long-term abrasion - a perfect fit for the custom braided cable assemblies we develop. And as computer control provides greater precision and superior handling, cable assemblies require secure connections that ensure critical devices, including cranes, lift stations, pumps, fans and all sorts of pneumatic and hydraulic equipment, will operate as needed, when needed.

We develop industrial cable assemblies for any kind of equipment, including automated tools that rely on DeviceNet or Ethernet. We custom braid cable to improve abrasion resistance and tensile strength, and can incorporate custom colors to make installation and maintenance easier. Almost every type of connector, including M8 / M12, LEMO and Fischer connectors, as well as waterproof and hermetically sealed connectors, are available. Soldering and crimp joints can be pre-molded, potted and overmolded, providing flexibility and strain relief while increasing stability and durability. We can pot the premold area to increase weatherproofing, create potting fixtures in specific shapes, and pot junction boxes to increase the integrity of the entire system, meeting whatever standards are required, including IP67 waterproofing and IP68 immersion specifications. Overmolding not only improves the integrity of your assembly, it can extend your brand. We can develop custom dies to permanently embed a logo or text into your cable assembly.