Value Engineering Services

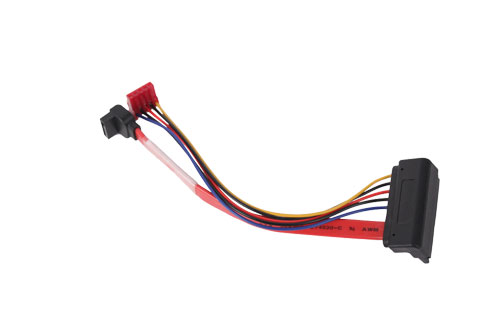

Custom Molded Cables

From extreme environmental stresses to the strains of abrasion and high-repetition movement, molded cable assemblies must be built to last. Without rigorous attention to the demands found in the field, a single cable assembly can lead to downtime, lost productivity and decreased ROI. That’s why Cypress Industries ensures that each custom cable assembly is designed, manufactured and tested according to the strictest specifications.

We review all of the demands imposed on each cable assembly, and bring a wealth of options to the table. After choosing the right materials (we work with PVC, rubber, santoprene, ABS, Polycarbonate (PC), Macromelt and many others) we identify the best production processes. Each stage of premolding, potting and overmolding is reviewed. We provide the right mix of waterproofing and abrasion resistance, meeting IP67 and IP68 standards if necessary. Soldering and crimp joints are examined, and premolding, overmolding or both can be incorporated to secure the connections and provide strain relief, durability and a long, useful life. We can design custom potting fixtures machined in specific shapes, adding coatings to the potting fixtures to ensure a good release and a clean finish. We also provide potting of junction boxes to provide weather proof seals.

We provide virtually unlimited overmolding capabilities, including custom resins, custom colors and custom dies. These dies can include your logo to permanently brand your custom cable assembly, or useful labels that facilitate installation and maintenance. We can also provide custom overmolds for military spec connectors or circular connectors (38999). Of course, we also maintain a large library of standard overmolding tools that can be applied as needed.

The entire process - including custom tools - can be duplicated for manufacturing in our facilities in the U.S., China or India, taking advantage of decreased costs and turn times, including shipping. Our advanced ERP systems allow us to create first-article quality regardless of the manufacturing location; every build is identical to the last.

Rugged cable assemblies address the environmental challenges faced by the mining, oil, gas, wind and solar energy sectors. Vehicles of all kinds, from customized automobiles to the varied transports used by the military, can use custom cable assemblies to take advantage of emerging energy and communications technologies. Industries of all kinds, including the agricultural sector, rely on cables that have been customized to meet the demands of high-repetition systems. And the construction sector can realize significant increases in ROI when the pneumatic and hydraulic controls used in cranes, trucks and lifts have been designed to minimize downtime. It’s all about you equipment and your needs.

We provide a wide range of custom cable assembly options, including:

- D-Sub (9, 15, 25, 37, 50)

- Telco 25 pair, 50 pair, 100 pair (Cat 3 & Cat5)

- Mini Din,

- V.35

- Audio / Video

- IEEE 1394 / Firewire

- HDMI

- USB

- VHDCI / SCSI

- RJ 45 / Cat 5E, Cat 6 boots

- BNC, SNA, N, TNC

- Power Cables

- Military 38999

- Ribbon Cables

- Cable Harness Overmolding

- Custom Molded Cables

- Potted Cable Assemblies

- Molex Connectors

- AMP/Tyco Connectors

- Computer Cables

- M8/M/12 Circular Connectors