Value Engineering Services

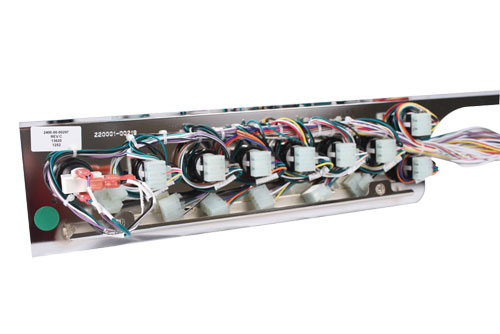

Gaming & Button Control Panel

Control panels must be designed to withstand any environment, from frigid ocean waters to the shuddering atmospheres of deep mining operations. But they can also be crafted to meet the needs of casino owners in the most carefully designed settings.

Cypress works with gaming industry professionals to develop chromed button panels of the highest quality. We verify the thickness of electroplating and copper flash to ensuring long-term reliability. We also produce nickel-plated button panels. We’ll develop gaming panels with buttons from existing manufacturers such as Suzo Happ™, or work with you to design buttons specific to your equipment. Of course, we also create programmable LED button panels to your specifications, or help you engineer the right solution for your gaming operations.

We develop custom fixturing to ensure rapid, high-quality assembly and keep costs down, and we can develop button panels to custom dimensions in our sheet metal facility. We use a blend of our manufacturing facilities in the U.S., Asia and India to manufacture, assemble and stock your systems, meeting your benchmarks for cost and turn time.

We integrate every type of button panel with durable wire harnesses, utilizing our advanced ERP system and performing inspections along the way, to make sure that the entire process is constructed the right way the first time, and every time thereafter. Buttons are installed with torque wrenches to make sure that each one meets exacting specifications, and we can glue components on request. We know that your equipment must meet stringent standards, so our operators wear gloves to prevent smudges and scratches during manufacture, then inspect every cosmetic Class I surface to make sure that they don’t leave our floor until they’re perfect. Whether you need Class I, Class II or Class III gaming equipment, we can build gaming control panels that will endure years of 24/7 operation.

- Our gaming button panel manufacturing process resides under one roof. We design, machine and assemble ourselves, eliminating the need for outsourcing. We’ll take your project from the drawing board to the field, providing tight control and superior quality at lower costs than our competitors.

- Our button panels are always tested and inspected at each stage of development, allowing us to identify problems and find solutions long before they’re put into service.

- We develop button panels from plated steels with chrome and brushed nickel as well as brushed stainless steel and custom plastics.