Value Engineering Services

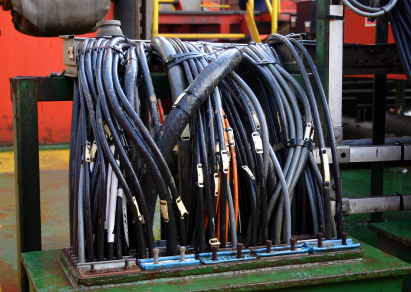

Oil & Gas Cable Assemblies

Hazardous and remote environments - from deep water oil rigs hundreds of miles offshore to land rigs and seismic operations in swamps and jungles - require equipment that defines the word “rugged.” Cypress Industries designs and manufactures oil and gas cable assemblies that withstand intense environmental stresses and provide durable, dependable service, minimizing downtime and increasing critical ROI.

We develop production methodologies that ensure your oilfield cable assemblies are perfectly suited to their use. Cable assemblies for oilfield drilling derricks, well sites, production platforms, offshore drilling or production platforms, mud pump rooms, logging trucks, logging cabs, mud pump trucks, mwd telemetry systems, lwd telemetry systems, seismic streamer boats or land seismic operations can be customized for your unique needs, including complex mux cables that allow you to operate with confidence.

Many oil and gas operations require umbilical cables to connect telemetry systems on equipment to drilling cabs and other monitoring rooms. These umbilical cables must be rugged enough to withstand extreme drilling and seismic environments - severing an umbilical cable can shut down a drilling rig, costing hundreds of thousands of dollars each day. That’s why our design and production teams take the time to fully understand each customer’s needs: to design the right cables for the right environments.

Cables can be braided to minimize abrasion and increase tensile strength. Premolds and junction boxes can be potted to improve water resistance, and we can design and manufacture custom potting fixtures in specialized shapes, adding coatings to ensure good release and a clean finish. Connections can be premolded and overmolded to keep soldering and crimp joints securely in place, and to provide strain relief over innumerable bend cycles. Specialized resins can be incorporated to provide added resistance to temperature, moisture and corrosion, meeting IP67 and IP68 specifications, and developing oil-resistant cables if needed. We can develop custom overmolds for military and circular connectors, among others. And we’ll overmold the assembly in custom colors and shapes, adding text or your logo to improve branding and facilitate training, installation and maintenance. No matter how rugged your environment, we’ll develop cables that can stand against it - we’ve got an experienced team that knows how.